2.12. Pilot Project: Elaboration of the Process and Logistics Options for the Im-plementation of the System for Collection and Utilization of PCB Wastes and PCB-Containing Equipment in the Russian Arctic

The Project Goal was to develop a mechanism for the implementation of priority projects in the context of the soon to be completed preliminary works for the ratification of the Stockholm Convention by the Russian Federation, including:

- Estimating the amount of PCB wastes and PCB-containing equipment in the Russian Arctic;

- Preparing the Schematic Map indicating the main storage locations of PCB wastes and PCB-containing equipment in the Russian Arctic;

- Preparing an organizational and methodological framework for the establishment of a management system for the collection and utilization of the PCB wastes and PCB-containing equipment in the Russian Arctic including removal of PCB from the electric equipment and tanks, utilization of liquid PCB, utilization of capacitors, transformer and tank components, flushing of transformers;

- Evidence-based process and logistics proposals as the best application options for the Arctic with due regard for the earlier proposals for the collection and utilization of PCB wastes and PCB-containing equipment;

The project was implemented by OOO “Research and Production Facility “Centre for Landscaping and Waste Management”.

The Project Duration 07 July 2010 to 30 November 2010

The Project Activities

- A review of the Russian and international experiences in the collection and destruction (utilization) of PCB wastes and PCB-containing equipment in the Russian Arctic to identify best practices for use in the Russian Arctic.

- A review of the existing regulation framework for the collection and elimination (utilization) of PCB wastes and PCB-containing equipment in the Russian Federation and development of priority proposals for its improvement with due regard to the provisions of SAP-Arctic and international experience including the outcomes of the earlier projects.

- Inventory of PCB wastes and PCB-containing equipment in the Russian Arctic; preparation of the schematic map indicating the main storage locations of PCB wastes and PCB-containing equipment in the Russian Arctic;

- Review of the best available technologies for the utilization of PCB wastes and PCB-containing equipment.

- Assessing whether it would be more practical to refill transformers rather than to destroy them; providing for technical options of cleaning transformers and disposing of PCB extracted from the transformers, as well as of destroying capacitors;

- Preparing analytical materials and rationale for proposals to select the best available technologies and technical options, while estimating the required number of installations/plants, the number of stationary and/or mobile installations and their locations;

- Holding a meeting on the outcomes of the Pilot Project involving the relevant environmental authorities and stakeholders;

The Project Outcomes

In line with the objectives and Action Plan of the National Arctic Policy of the Russian Federation, it will be necessary to establish a comprehensive security system to protect the territory, population, and facilities in the Arctic from the risks of natural and man-made disasters. In the context of environmental safety, it is necessary, in particular, to provide for the disposal of toxic industrial waste and chemical safety in the residential areas.

An inventory of waste in the Russian Arctic must serve as the main database for tackling the problem. The Inventory will assess the quantity and composition of wastes, their location, identify the owners of wastes, and, most importantly, will legalize the presence of wastes. The Inventory will help regional administrations to make informed decisions concerning destruction or disposal of wastes.

Information obtained as a result of this work will be used in calculating the economic costs of environmental activities such as the procurement of equipment, collection and classification of waste, shipping them to the processing site, etc.

The assumed PCB wastes in the Russian Arctic are leftovers from human activity. These are likely to include the remains of buildings, electrical substations, boiler houses with heating systems, tanks, containers, drums with oil residues and Sovol, as well as oils containing polychlorinated biphenyls (PCB). PCB-containing Sovols were used in transformers and other equipment, electrical substations, and in heating systems, as good non-freezing coolant. They have not been manufactured in this country since 1993.

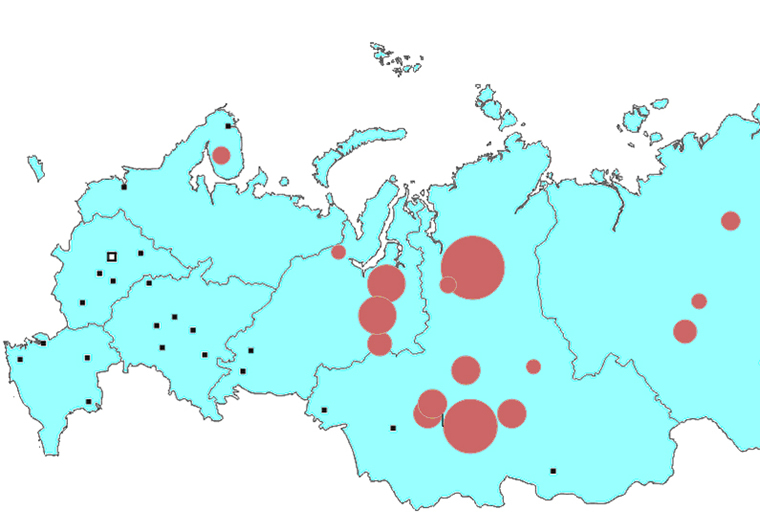

Figure 40. Schematic Map of PCB and PCB-Containing Electric Equipment in the Russian Federation

In three nearby Central, Northern, and North-Western Federal Okrugs, there is more than 4,000 ton of PCB in PCB-containing equipment used and stored in the chemical and petrochemical industries, ferrous and nonferrous metallurgy, machinery, forestry sector. The 2000 inventory of PCB and PCB-containing equipment established that there was PCB-containing equipment (transformers and capacitors) in Murmansk Oblast, Yamalo-Nenets Autonomous Okrug, Krasnoyarsk Krai and the Republic of Sakha (Yakutia). In the territories that are part of the Russian Arctic, there is about 1,269 ton of PCB. Almost the entire PCB stock was found in Krasnoyarsk Krai - 990 t (78% of the total) and in the Yamal-Nenets Autonomous Okrug - 235 t (18,5%). It may be assumed that these figures are not very precise, and most likely underreported. It will be necessary to make a comprehensive and detailed inventory and registration of PCB and PCB-containing equipment and their locations in the Russian Arctic. This inventory should serve as a basis for the development of a detailed PCB destruction action plan.

The pilot project also conducted an analytical review of the regulatory requirements to safe storage of stockpiles of PCB and PCB-containing wastes in the Russian Arctic, including requirements to a full range of necessary actions for the disposal of PCB-containing equipment: draining PCB, washing the equipment, neutralizing the equipment (including transformers, capacitors and empty PCB containers), and destruction of PCB and PCB-contaminated waste. A very important aspect of PCB waste disposal in the Russian Arctic is to develop special requirements to the system of collection, transportation, storage and destruction of PCB and PCB-containing equipment. There are currently no such requirements.

High-temperature processes are used to directly process such toxic chemicals as PCB. Self destruction of polychlorinated biphenyls will be at a temperature that is not less than 1100 ° C and PCB should be in the reaction zone for at least 1-2 seconds. In this way, there will be no secondary dioxins (PCB belongs to dioxins) generated.

In the international practice of thermal decontamination, the following process options are applied for such compounds: fired-heater reactors, fired-heater reactors with additional plasma afterburning of off-gases, fired-heater reactors with additional plasma heating of the reaction mixture, and plasma-arc reactors. All the PCB processing installations in the Russian Federation are experimental and none of them has currently a positive conclusion of the state environmental review.

The pilot project report discussed matters related to the organization of environmental monitoring at those locations in the Russian Arctic where PCB and PCB-containing equipment are operated, stored and disposed of. There is also a review of the regulatory requirements. It is noted that Russia operates only 4 specialized laboratories capable of environmental monitoring of PCBs and dioxins. To ensure the technical capacity of PCB monitoring at the facilities that operate PCB-containing equipment, as well as in the storage and disposal areas, it will be necessary to furnish the existing specialized laboratories with modern analytical instrumentation and to establish new laboratories staffed with skilled professionals.

The Report also describes the evidence-based process and logistics proposals as the best application options for the Arctic with due regard for the earlier proposals concerning the collection and utilization of PCB wastes and PCB-containing equipment. They include themes such as the selection of PCB destruction technologies, technologies for the treatment of transformers, treatment or destruction of capacitors, including matters related to the feasibility studies of such activities, performance of individual modules, number of individual installations and selection of sites for the disposal of PCB and PCB-containing wastes.

The proposed scheme of preparation for PCB waste thermal disposal of in the Russian Arctic includes:

- Selecting a thermal destruction installation;

- Establishing a thermal destruction station comprised of two 500 kg/h (at least) furnaces with (the capacity will be specified after the PCB waste to be destroyed has been identified); two furnaces are required because the furnace refractory life is usually not more than 6000 hours (one furnace is under repairs, the other is in operation). A thermal destruction station should be located in an industrial area of one of the nearby cities after having selected the best distance for waste transportation.

- Collecting PCB in special containers in places where it is kept and delivering PCB to the thermal destruction station;

Another important focus in waste collection is degassing empty PCB containers after PCB has been drained (drums, containers, tanks, etc.). This problem should be dealt with in parallel with the main objectives since the degassing solution must also be thermally destroyed.

In order to have a full environmental insight in the process of establishing the PCB inventory, it will be necessary to take soil samples for PCB to decide whether remediation of soil is required. If PCB is found near a water body, PCB water samples must also be taken.

The main difficulties in this work will be to obtain information about PCB-containing wastes and select a site for the construction a PCB thermal destruction station. Therefore, good motivation proposals will be needed to address these issues.

| « Previous | Next » |